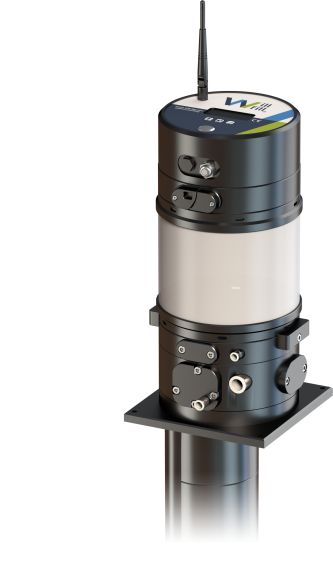

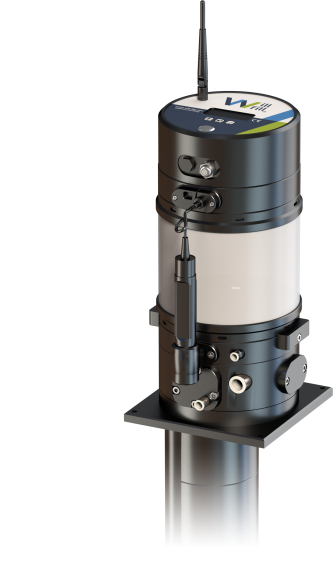

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Autonomously performs a filling with the perfectly calculated oil/water ratio required to maintain the specified concentration once topped up

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Equipped with Advanced PID software.

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

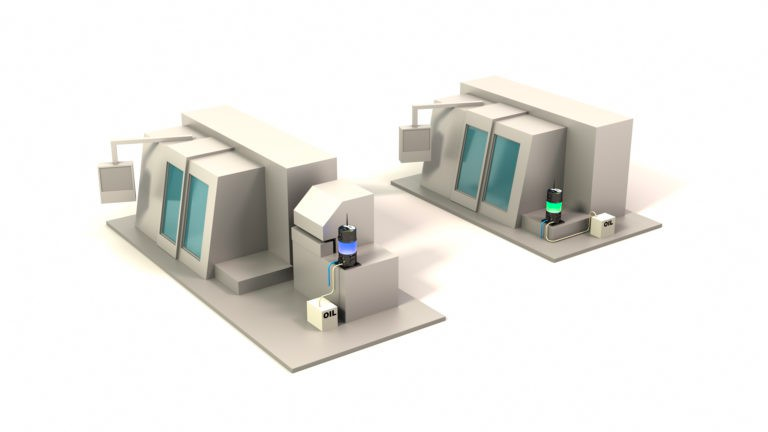

Will-Fill designed for single machine setup and the total volume is direct calculable

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

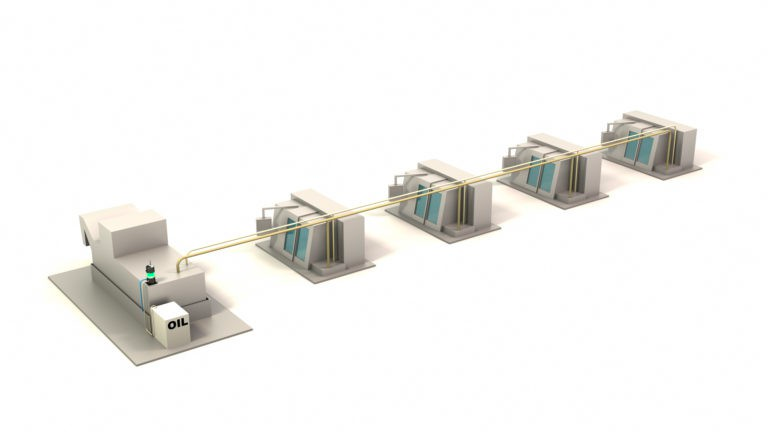

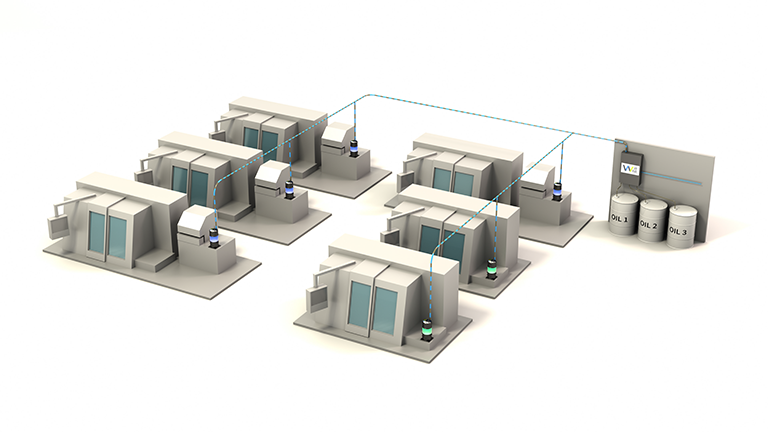

Will-Fill designed for multiple machine setup and the volume is not direct calculable

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Small top-ups to ensure that there will be no thermal shock by adding cold and fresh emulsion

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Detects abnormal consumption, which may indicate a failure of the connected metalworking fluid process

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Periodically re-mix and aerate your emulsion to prevent bacterial formation at a standstill

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

The newly introduced emulsion oil and the new water are always mechanically mixed with the existing emulsion

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Send E-mail notifications of each event where a human interaction is requierd

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Uses interval measurements and history measurements to determine the required concentration values for a top-up

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Can be setup as measuring equipment only

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Is equipped with advanced firmware to predict your preventive maintenance

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Based on calculations the device will determine the amount of emulsion oil is still available

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD

Based on measurements the device will determine the amount of emulsion oil still available

Will-Fill NEO

Will-Fill ION

Will-Fill AIO

SD

MD

SD

MD